Photoreactions

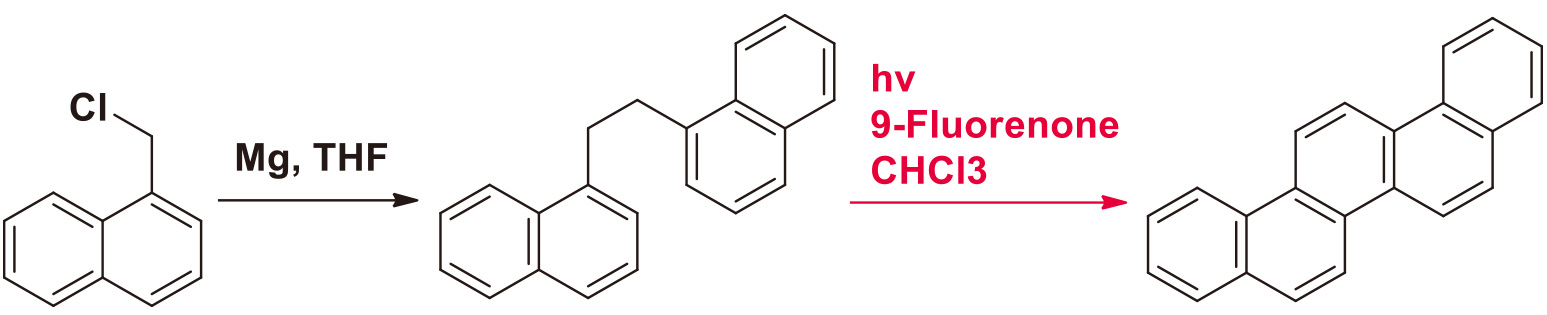

Batch reactors are often used for obtaining phenacenes. However, the reaction speed is significantly low in a batch reactor due to the increase in reaction liquid concentration. This leads to increased usage of electricity because of prolonged reaction times. When the reactions are conducted in batch reactors, the frequent turning on and off of the lamp reduces the life of the lamp. These problems can be largely avoided if photoreactions are conducted in large-scale synthesis.

Our company is equipped with both batch and flow reactors. We provide methods that are suitable for the requested reactions. Previously, we developed photoreactions using a flow reactor for synthesizing phenacenes, which reduced the reaction times and increased yields when compared with the batch reactors.

Based on these achievements, we propose more effective synthesis by selecting methods appropriate for the characteristics of the reaction.

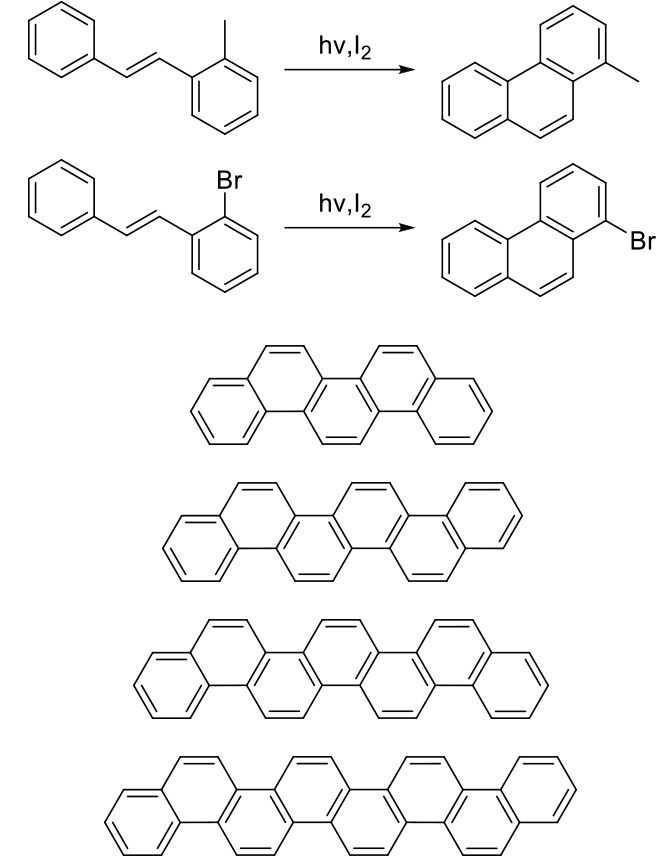

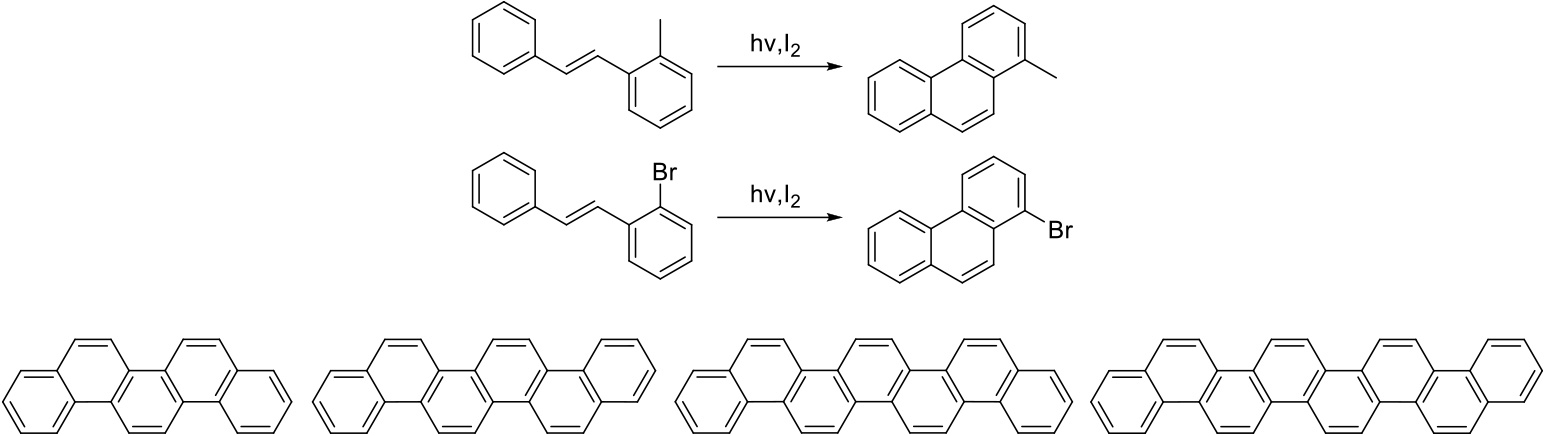

Synthesis of picene

Synthesis pathway

Issues with photoreactions in a batch reactor

- The reaction speeds significantly decrease as the reaction liquid concentration increases.

- In large reaction vessels, light cannot evenly reach all areas.

- In large reaction vessels with powerful lamps, the generated heat can be difficult to control.

Large-scale synthesis of organic substances is difficult using batch reactors.

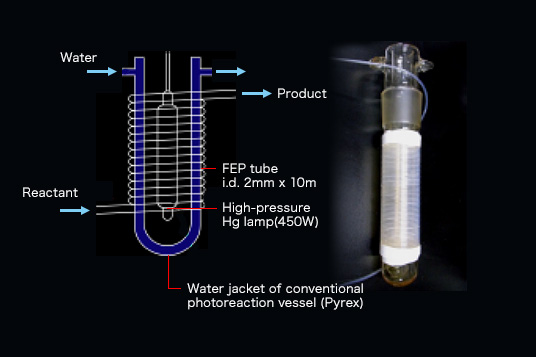

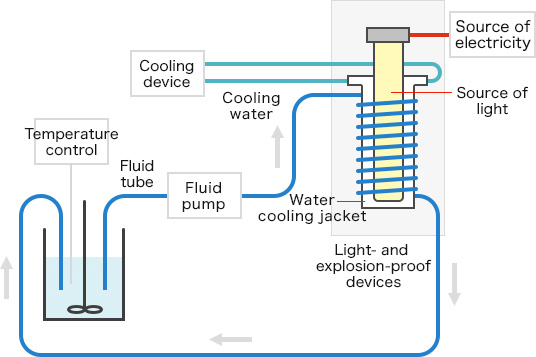

Photoreaction in a flow reactor

Reaction fluid is pumped through a tube encircling the light source.

Examples of photoreactions in a flow reactor

Outcomes

| Reduction of the reaction time | Easy purification |

| Improved yield | Easy scale-up |

| Desired compounds were obtained at an equivalent yield without using PO, which is necessary in case of a batch reactor to improve the yield | |

Related contents

Inquiries about products and technologies

Please contact us for consultations and inquiries regarding products and technologies.