Selling of sublimation purification equipment

We propose sublimation purification equipment based on our experience and the concepts of our organic synthesis chemists.

Based on precise temperature control, we can obtain highly purified organic compounds.

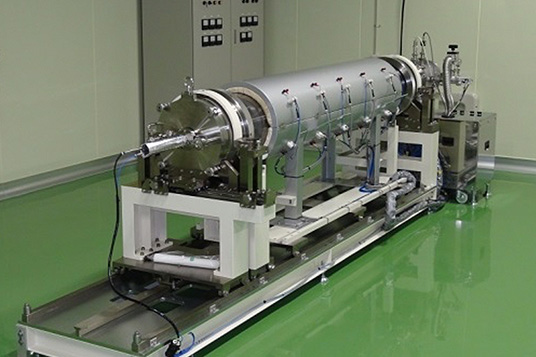

Structural components of the sublimation purification equipment

- 1. Sublimation device

- 2. Ring heater

- 3. Vacuum exhaust device

- 4. Cooling trap

- 5. Electronic control device

Features

- 1. High yield based on the original technology

- 2. Precise temperature control using an optimized heating component

- 3. Maximum prevention of the pyrolysis of substances using a vacuum pump

Applications

| Organic EL |

| Organic solar battery |

| Purification of the organic semi-conductors for organic transistors |

| High purification of monomers for polymer synthesis |

Standard model specifications

| Model | HX05 | HX10 | HX20 | HX30 |

|---|---|---|---|---|

| External diameter of the sublimation tube | 50mm | 100mm | 200mm | 300mm |

| Approximate capacity | 10g | 100 - 500g | 500g - 2.5kg | 1kg - 10kg |

| Heater zone | 3 - 5 zones | 3 - 5 zones | 3 - 7 zones | 3 - 9 zones |

| Upper limit of heating | 450℃ | 450℃ | 450℃ | 450℃ |

| Vacuum pump | Rotary pump Diffusion pump |

Rotary pump Diffusion pump |

Rotary pump Diffusion pump |

Rotary pump Diffusion pump |

| Degree of vacuum | Less than 10-6 torr | Less than 10-6 torr | Less than 10-6 torr | Less than 10-6 torr |

Related contents

Inquiries about products and technologies

Please contact us for consultations and inquiries regarding products and technologies.